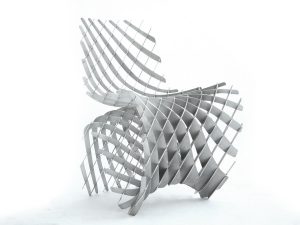

Joris Laarman (Dutch, b. 1979), Structural Study for Maker Chair (Mesh), 2014. Aluminum; 30 3/4 x 23 3/4 x 25 1/2 inch. New Orleans Museum of Art, Museum purchase, William McDonald Boles and Eva Carol Boles Fund, 2020.2. Photo credit: Courtesy of Joris Laarman Lab and Friedman Benda. © Joris Laarman Lab

When chemists first successfully extracted aluminum from the earth in the 1850s, the raw element was as precious as gold. Today we take aluminum for granted, though it allows for nearly every facet of modern life through its use in architecture, industry, and transportation. From the nineteenth century until today, artists and designers have increasingly turned to aluminum because its unique properties–lightweight, strong, can be pressed thin, resistant to corrosion–allow for the exploration of new ideas through objects.

NOMA’s exhibition Atomic Number 13: Aluminum in 20th-century Design (Elise M. Besthoff Gallery, opened April 23, 2021) charts the use of aluminum from being a rare element used only preciously through its heyday as an affordable material for cocktail shakers and office staplers. By the late 20th century continuing until today, aluminum is well established as a stable medium for outdoor sculpture, as seen throughout NOMA’s Sydney & Walda Besthoff Sculpture Garden, and as a versatile material for artistic experimentation, like this 2014 prototype Maker Chair by Joris Laarman in NOMA’s collection.

Joris Laarman and his team focus on research and experimentation. Based in Amsterdam, the Laarman Labs is known for pioneering applications of digital technologies and emergent making techniques–processes like 3D printing, computer directed CNC milling, or even just the concept that today’s makers can think with the aid of computers. The Lab started the Maker Chairs series in 2014, around the time that 3D printers and CNC machines became available to non-industrial consumers, available at places like the local hardware store.

The concept behind Maker Chairs is that each design could be produced using digitally-linked technologies–3D printing or CNC milling in wood, plastic, or metal–at home from one’s own computer and simple machines. Instead of requiring large specialized production for a full-scale chair, each Maker Chair design is composed of small parts limited in size to the capacity of affordable machines available on the domestic market. In other words, you or I could make these dynamic chairs at home.

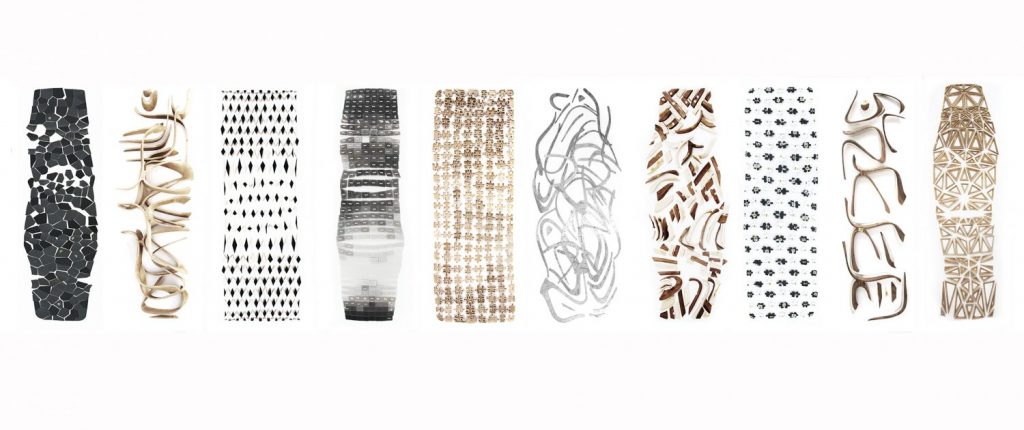

The parts for NOMA’s chair are represented in the photo 6th from the left. Outlay of Maker Chair parts, 2014. Photo credit: Courtesy of Joris Laarman Lab and Friedman Benda. © Joris Laarman Lab

Once an at-home maker produces (prints or mills) the individual chair parts from the digital files, they have a 3D puzzle that builds an extraordinary chair. Maker Chairs are designed for various materials and in different configurations, but the overall shape, the dramatically skewed S, is the same across material. NOMA’s chair is the “Mesh” version composed of small S and C shapes of cut metal (aluminum). Other Maker Chairs with names like “Pixel,” “Diamond,” “Hexagon,” or “3D Puzzle” are pieced together from CNC-milled wood or 3D-printed plastic pieces.

Maker Chairs, 2014. Photo credit: Courtesy of Joris Laarman Lab and Friedman Benda. © Joris Laarman Lab

NOMA’s Structural Study for Maker Chair (Mesh) is a test, or prototype, of the design, and the only one made in aluminum. Joris Laarman Labs originally conceived of “Mesh” to be made in magnesium, a metal with about two-thirds the density of aluminum, so issued an initial prototype in magnesium that is now in the collection of The Museum of Fine Arts, Houston. The Labs note that “the design and strength [of magnesium] didn’t allow for daily use.” NOMA’s chair is their experimentation making “Mesh” in aluminum for added strength, but “in the end this did not give the desired result either, so we decided to keep the magnesium version with a slightly modified design and have it as a sculptural piece instead of a daily use chair.” In 2014 Laarman’s team issued an edition of 16 Maker Chair (Mesh) chairs in a magnesium alloy.

Though the designer fabricated and issued his own versions of the design, an important concept for the Maker Chair series is non-exclusive access to the design process. Laarman Labs made digital plans for the chair available to everyone, believing that accessibility and repetition would make the design better. The Laarman Labs website states it this way:

In the tradition of the early modernists, who often created manuals of their designs so that people could replicate their work at low cost, the blueprints of the 3D-printable versions of the Makerchairs were made available on the Internet under a creative commons license for people to download, modify and manufacture themselves. In that sense this chair is a work in progress and we invite everyone to help make them smarter and more diverse.

As a key part of the Joris Laarman’s practice is experimentation with materials, NOMA’s Structural Study for Maker Chair (Mesh) was included in the major museum travelling exhibition Joris Laarman Lab: Design in the Digital Age. The exhibition originated at the Groninger Museum in The Netherlands in 2015, and travelled to the Cooper-Hewitt Smithsonian Design Museum in New York, the High Museum of Art in Atlanta, and the Museum of Fine Arts in Houston.

—Mel Buchanan, RosaMary Curator of Decorative Arts & Design

NOMA is committed to uniting, inspiring, and engaging diverse communities and cultures through the arts — now more than ever. Your gift will make a direct and immediate impact as NOMA welcomes our community back to the museum and sculpture garden, plans new exhibitions, and develops virtual and at-home arts education resources for school partners.